Symptoms/Issues

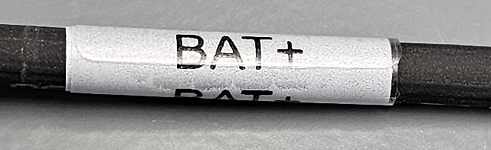

- The label "telescopes" around the wire

- The label feeds but does not catch the wire

- Labels wrap loosely or fall off the wire

Best Practices

Please heed the following tips as not doing so may effect the quality of your wrap:

Troubleshooting

1. Printer Adjustments

Make a Feed to Wire adjustment or increase the cycles per wrap:

2. Preventative Maintenance

Clean the printer:

3. Labels and Wires

Additional Troubleshooting

- The wrapping mechanism may not be revolving around the wire or cable enough times to adhere the full length of the label. Adjust the Wrap Count (Settings > Print Adjustments > Wrap Count).

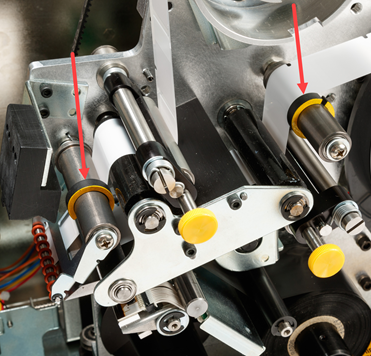

- Guide rings may not be adjusted on the guide rollers to hold the label material in place. This can cause the printer to be unable to detect the notch in the label material and move the label material the wrong amount. This in turn, can cause the labels to wrap incorrectly.

- In some cases poor wrap quality can be caused by outdated firmware or required mechanical adjustments. If you have more than one A6500/Wraptor unit and the issue only occurs on one, this is a good indicator that the issue is caused by mechanical or firmware adjustments specific to one unit.

If the issue persists, contact Brady Technical support for your region for additional troubleshooting or to setup a repair authorization: Global Brady Technical Support (Contact Information) and provide the serial number How to Locate the Serial Number on the A6500.

Related information