Preventative Maintenance - Lubrication

Some Wraptor printer parts will need occasional lubrication in order to keep the unit running smoothly. Check the following items for proper lubrication every 6 months to one year.

Important: Do not over-lubricate any of the parts. Make sure to wipe off any excess oil or grease. Over-lubrication or lubricant in the wrong place can result in printer malfunction.

Note: These procedures require you to remove the label material and ribbon prior to performing maintenance.

Oil the Slide Track

The slide track carries the print mechanism back and forth. Although it comes pre-oiled, you should inspect it and re-oil as needed.

-

On the touch screen, select Load Supplies and then select Load Supply. This shuttles the print and wrap mechanism back.

- Power off and unplug the Wraptor™ A5500 or A6500 printer.

- Open the side door on the printer.

- Remove the ribbon.

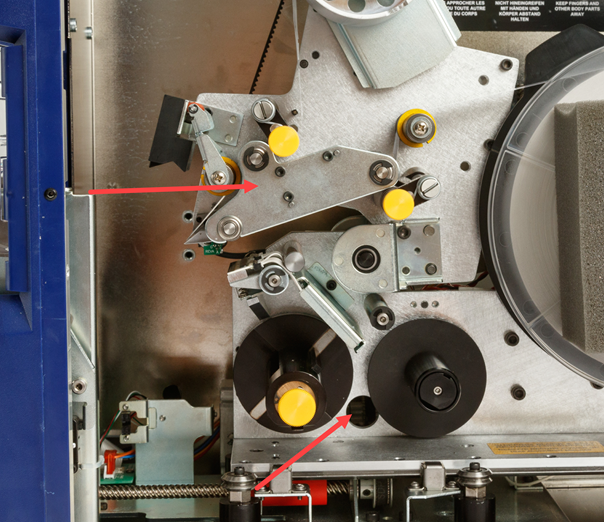

- Inspect the two oilers (shown below) on the outside of the slide track.

- If dry, add a few drops of light machine oil.

Note: There are four oilers. Two are on the outside of the slide track (shown below), and two are located opposite these on the inside of the slide track.

- Inspect the two oilers on the inside of the slide track:

- Manually shuttle the slide track back until the access hole (on the bottom of the track) is aligned with the front inside oiler.

The area may be harder to access, so something that is longer must be used to place a drop of machine oil.

- Manually shuttle the slide track forward until the back inside oiler is exposed. The back oiler can be accessed underneath the print and wrap mechanism towards the back.

- If dry, add a few drops of light machine oil to each oiler.

- Close the side door.

Clean and Grease the Wrapper Hub

- On the touch screen, tap Load Supplies and then tap Load Supply. This shuttles the print and wrap mechanism back.

- Power off and unplug the Wraptor™ A5500 or A6500 printer.

Important: You must power off and unplug the printer before performing any maintenance or cleaning.

- Open the front (clear) door on the Wraptor™ A5500 or A6500 printer.

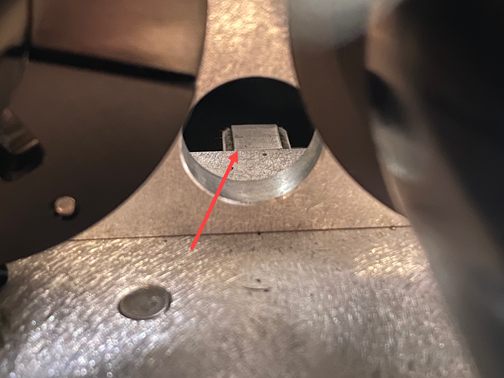

- Clean the two surfaces of the “V” on the wrapper hub with a soft, lint-free cloth or a clean swab dipped in isopropyl alcohol.

- Apply high pressure grease to a soft, lint-free cloth or a clean swab.

- Using the greased cloth or swab, apply a very thin layer of grease to the wrapper hub as you rotate it. Make sure not to get any grease in the opening of the hub.

Important: If too much lubricant is used, the printer may not apply labels properly.

Related information