Body | Labels do not Adhere to WireWhen using the Brady Wraptor and labels are not adhering tightly to the wire/cable when inserted into the machine, users may try the following adjustments;

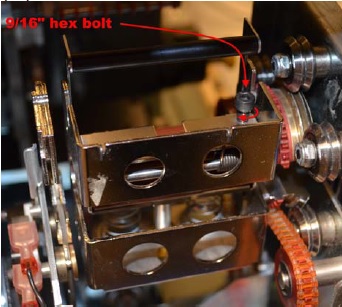

The 'Set Screw' adjusts how much pressure the springs put on the 'v-block', because the label is presented between the orange 'v-block' pad and the wire/cable, allowing the springs to exert the maximum pressure will yield the tightest wrap. Try turning the 'set screw' counter-clockwise to increase pressure against the wire/cable. (See Image below)

Also, users may find that increasing the 'Feed to Wire' value slightly, may improve the wrap quality on the cable/wire being used. The 'Feed to Wire' adjustment causes the label to present past the center of the cable/wire, which is the default location. When the label is presented further past the center of the cable/wire, it may grip the cable/wire better and yield a tighter wrap.

To make this adjustment; Touch the 'ADJ' tab at the top of the Wraptor's touchscreen. Then touch the 'Advanced' button onscreen to view the 'Feed to Wire' value. Touch the (+) key onscreen to make a minimal adjustment. Start with a small adjustment and then run a couple sample wraps to see if had the desired effect.

The 'Set Screw' is shown below:

See Also:A6500 - Adjust Feed to Wire AdjustmentA6500 - Increasing Cycles Per Wrap See Also:A6500 - Adjust Feed to Wire AdjustmentA6500 - Increasing Cycles Per Wrap |

|

|---|