Issue

The A6500 has issues feeding the materials or labels do not feed onto the wrapping mechanism.

Troubleshooting

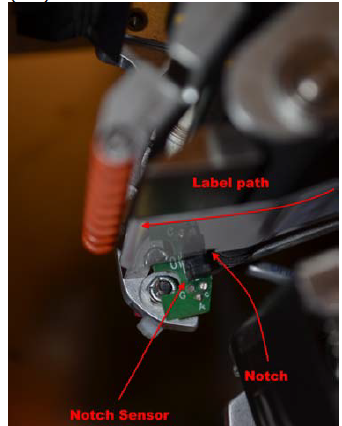

- Clean the Notch Sensor.

It is recommended that you clean the sensors every six months to one year. If the sensor is blocked from adhesive residue, dust, label lint, you will encounter feeding problems because the sensor can not detect the notch on the left hand side on the liner of your label reel.

The wrapper contains this sensor that will require occasional cleaning.

-

- Open the front and side doors of the unit.

-

- Locate the label notch sensor using the graphic below as your guide.

-

- Clean the label notch sensor with the swab from the cleaning kit (PCK-6).

-

- Continue to clean the other sensors as needed.

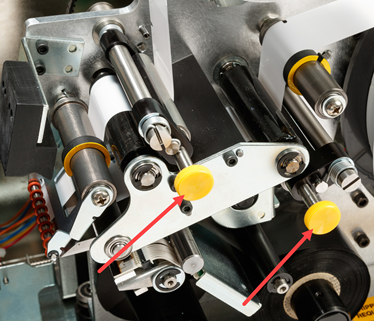

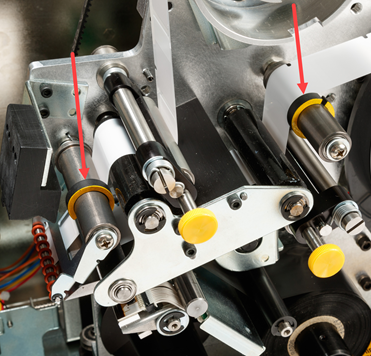

- The nip rollers may not be fully engaged. If the nip rollers are engaged but not applying sufficient pressure for the label material to feed along the drive rollers, contact Tech Support: Global Brady Technical Support (Contact Information).

- Guide rings may not be adjusted on the guide rollers to hold the label material in place. This can cause the printer to be unable to detect the notch in the label material and move the label material the wrong amount. This in turn, can cause the labels to wrap incorrectly. Wraptor A6500 - How to Load Labels.

- Verify the deflector guide is in the correct position.

Still Not Working?

These mechanical issues can also cause feeding problems:

- Broken ribbon rewind spindle

- Outdated firmware

- Worn V-block

- Worn Platen Roller

- Worn Driver Roller back

- Worn Drive Roller front

- Sleeves Obstructing Jaws

- Mossing O-rings from label deflector

Contact Technical Support to setup a repair: Requesting a Repair Authorization for a Brady Benchtop Printer and provide the serial number How to Locate the Serial Number on the A6500.