Ribbon Feeding Out with the Material / Cutting Material

Issue/Symptoms

The ribbon adheres to the label and is fed through the cutter chute. If the ribbon is fed far enough it will be cut along with the labels when the cutter actuates.

Affected Products

This issue can occur due to lack of maintenance on any THT printer with an auto cutter (BBP30, BBP31, BBP33, BBP35, BBP37, i3300, S3100 and S3700). This article scope is limited to this issue exhibited from the included printer models, however the general troubleshooting and resolution extends to other THT auto cut printers.

Troubleshooting

The Ribbon Sticks to the Label Liner

First check to see if the ribbon is sticking to the label material as it is printing and feeding. If it is sticking, there may be an issue with adhesive oozing from the edges of the material. Check to see if there is transfer around the edges of the labels that have printed prior to the ribbon sticking. For more information about adhesive ooze and its causes, see: Adhesive Bleeding/ Label Sticking on Die Cut Material and What is the Shelf Life for Brady Labels?

It is also possible that the ribbon is sticking due to overheating of the printer. Also, if the printer is used frequently and then sits for an extended period of time, the label and ribbon that are underneath the print head may become fused and cause the ribbon to feed. As a best practice, we recommend disconnecting power from or unloading materials from the BBP30, BBP31 and BBP33 model printers when they are not in use.

Cleaning

These printer should be regularly cleaned In addition to the above steps. This is an industrial printer with industrial strength labels and adhesives. Once adhesive is in the printer, you want to clean it thoroughly with isopropyl alcohol. We recommend cleaning the printer after every 2 rolls of labels.

Label Roll Alignment

Verify the end caps are snug against the label roll. If there is a gap between the end cap and the label roll, push the end caps in so the label roll is centered and the end caps are snug against the labels.

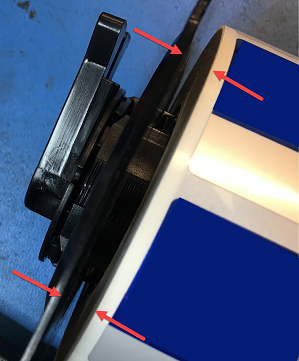

Gap between Label and End Caps End Cap Adjustment

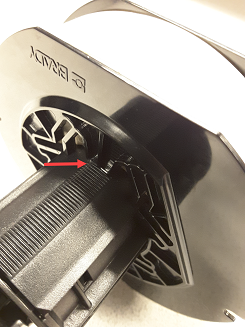

Wiper Arm

When using die-cut labels, the wiper arm should not be down because this can cause the front lip of the label to peel and stick to the ribbon.

Media Mismatch

Different label materials require different ribbon series for proper printing. It is important to ensure that you are using the correct series to avoid quality issues.

The Ribbon Feeds But Does Not Adhere to the Labels

If the ribbon is feeding out but not sticking to the labels as it prints, this indicates that the printer has a mechanical issue with the take up spindle that winds the used ribbon. A new ribbon will not correct this issue and the printer will require repair: Requesting a Repair Authorization for a Brady Benchtop Printer.

Important: The BBP30, BBP31 and BBP33 printers are no longer repaired or supported: Obsolete Brady Printers - No longer supported or repaired.

Contact Global Brady Technical Support (Contact Information) for further assistance with the serial number of your printer: How to Find Your Brady Printer Serial Number.