Note: In addition to sensor position, you may need to confirm sensor settings are properly configured in the i7100 Setup menu accessible from the touch screen: Gear Icon | Setup | Labels | Label Sensor.

IMPORTANT: Unlike most non-smartcell / RFID driven printers (Brady printers that read computer chips or RFID tags in Brady Label Rolls to automatically set page size, orientation, and a sensor type setting which can be either a non-movable sensor in the center or a moveable "bottom reflect / notch / black mark" sensor), the i7100 printer ONLY has one sensor. If the materials have a gap, the sensor setting in the menu should be Gapped; if the printer has a notch, the sensor should be Bottom Reflect; Continuous labels have the continuous sensor. With continuous material, since there is no spaces between separate labels on the liner, there is no need to calibrate - it does not matter where the label starts printing to make sure everything lands on the label.

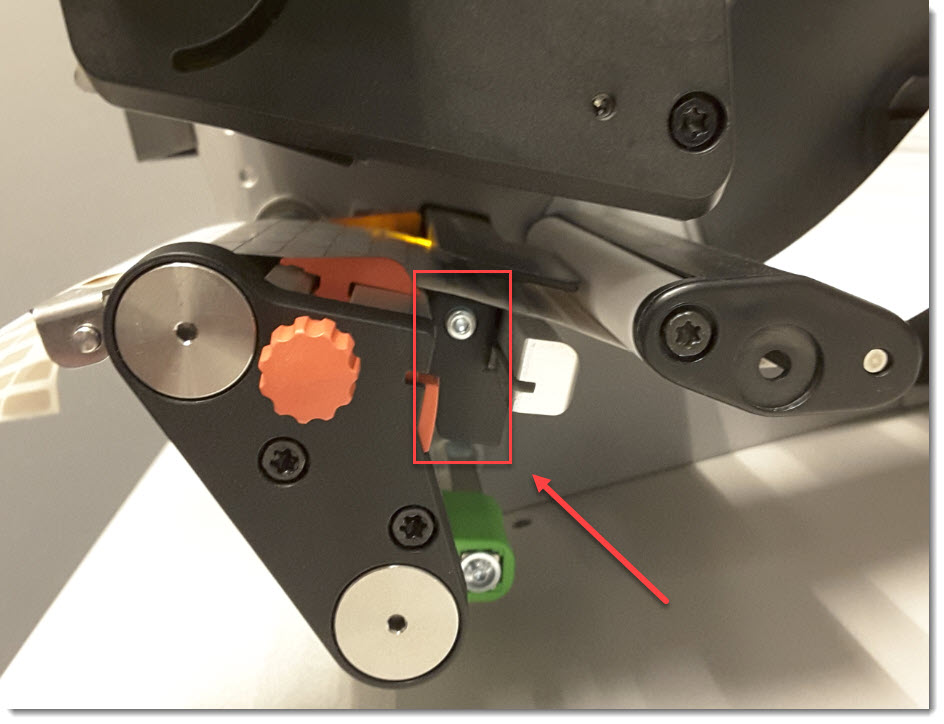

i7100 Sensor Positions for Accurate Calibration

The sensor is indicated by an orange LED. This sensor is adjustable using a black tab accessible from the right side of the printer.

Notched

Place the sensor so that it sees the notches on the left-hand side of the label liner.

Multi-column Gapped

Place the sensor so that it is centered over one of the labels and measures the light coming through between rows of labels. Do not place the sensor so that it is over the vertical gap between two columns, or it will not detect change in light that comes through between labels.

Sleeve Material

Position the sensor so that it sees the square cut outs between each sleeve on the left-hand side of the liner. Do not place the sensor over the circular tractor-feed holes used to manufacture the sleeves, nor the window in which the sleeve is attached.

Single Column Gapped

Place the sensor anywhere over the label so that it detects the horizontal gap between labels.

Note: For pre-printed media, avoid placing the sensor where it will detect the color difference between the printed text or graphics and the label material.

Related information