Troubleshooting BBP11 and BBP12 Calibration IssuesCalibration issues:

- Loses calibration

- Feeding blanks

- Offset print

- Printing between the labels

- Truncation of the information being printed when printing labels.

- Objects are cut off the label.

Check This First

- Confirm standalone calibration: How to Calibrate the BBP11 and BBP12 Using the Diagnostic Software Tool.

- Make sure the correct driver version is installed and in use: How to Install the BBP12 Driver.

- Confirm the label part chosen in the software matches the label part currently installed in the printer.

Additional TroubleshootingCheck These Driver Settings (Die-cut or continuous only)

- Open Devices and Printers and right click on the BBP11/12 printer. (Start menu > Control Panel > View Devices and Printers).

- Choose the option of Printing Preferences.

- Click on the Page Setup tab on the upper left.

- Set the Stock to USER. Proceed to step 10.

If you currently have Stock set to USER and calibration is still off, define the stock and select New.

- Name the stock/label part.

- Choose the Type of label being used (die-cut or continuous).

- Enter the Width and Height of the backing.

- Enter the Left and Right spacing (spacing from the backing to the label) into the Exposed Liner Widths.

- Click OK. Select the new part in the dropdown and select OK.

- If the software is open, close and relaunch the software to ensure the driver pulls the correct label part/changes. You may need to print multiple labels to test the new settings, as the printer may use settings from the previous print job for the first label.

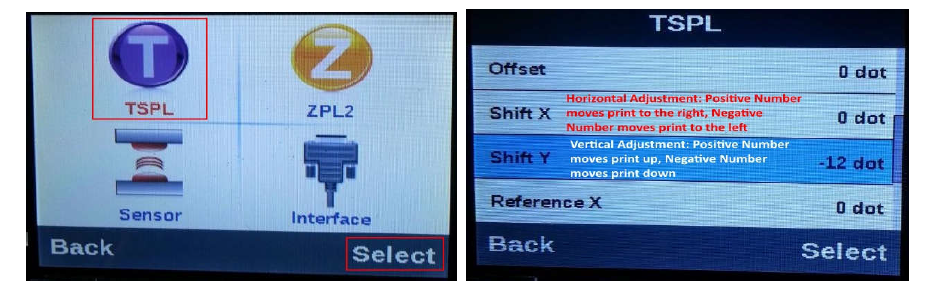

Making Print Position Adjustments from the LCD ScreenWe have found that out-of-the-box BBP12's often require minor offset adjustments to fine-tune print position. If the print is consistently coming out in the same spot on every label, but is too high or too low:

Make a Shift Y (vertical) adjustment in either the printer’s LCD Menu (shown below) or using the DiagToolBBP12.exe.

- For Shift Y, positive numbers move the print up on the labels, negative numbers move the print down

- If you need to move the print horizontally Use Shift X. For x positive numbers move the print right, negative numbers move the print to the left

You may also calibrate the printer or make print position adjustments (Shift Y for vertical, Shift X for

horizontal) in the DiagTool - the Diagnostic and Configuration utility that allows you to configure and

diagnose the BBP12 printer from a PC screen.Adjusting Vertical Print Position Using the Diagnostic UtilityThis can be done as an alternative to the LCD screen print position adjustment method.

- Go to Advanced Configuration tab: click Get.

- Enter a number in the “Shift Y” field then click Set. A positive number moves the print up, a negative number moves the print down.

Do not enter Print Position Adjustments in Brady Workstation or LabelMark's Print screen if you have to move the print more than just a small amount, if you have a very small label, or if you have data in the label close to the edges. Print Position adjustments in Labelmark and Brady Workstation will move the print as desired, but it also reduces the printable area by the same amount, and may result in print that is truncated, cut off. For print position adjustment best practices, see: Printing Adjustments - Best Practices & Troubleshooting.