Cut Alignment Issues with Raised Panel Labels on B30 Series Printers

There have been reported issues with printing raised panel labels on the BBP3X series printers, often including calibration and drifting print.

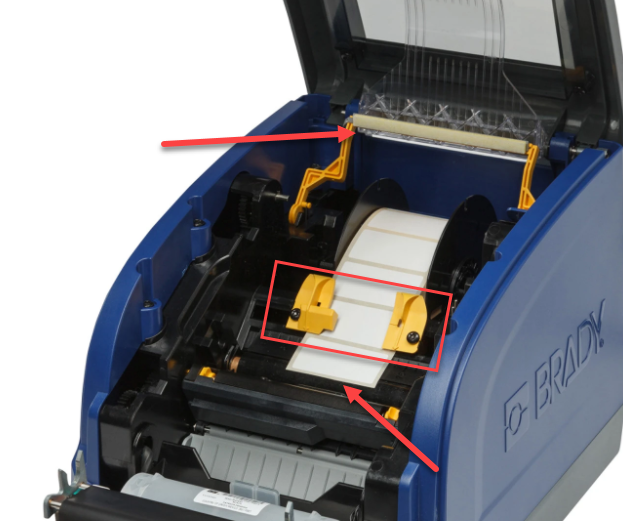

Make sure you have the material loaded correctly

- The yellow material guides should be snug on each side of the tape, but not pushing or changing the shape of the tape.

- The leading edge of the material should rest on the center of the black roller. If it is any further it may trigger printer errors.

- The wiper arm should not be engaged.

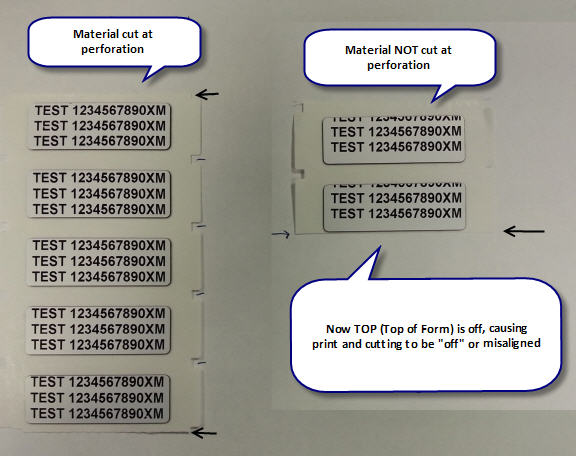

Make sure the leading edge of the tape is cut along the perforation

Make sure that the edge is clean cut along one of the perforated lines between labels. This will guarantee that the printer is not getting a bad read on the notch sensor when pulling the first label through. This also ensures cutting is aligned for each label.

Make sure you have the correct label part or page size selected in the software

When using Brady Workstation or LabelMark, make sure that you are pulling the correct part number. All B30 series printers support bidirectional communication. Use the "Installed" option in Brady Workstation. If for some reason bidirectional communication is not working, see:

Do not enter adjustments or offsets in the printer, print driver or software until you made sure the first three suggestions above have been followed. First, you must get the print to land consistently (even if it is consistently off). Only once print lands consistently can you begin to make offsets.

Change cutter mode to Cut Between Labels

Raised panels can become curved when in prolonged storage or when running through the printer. This is more pronounced on larger labels, but small labels are affected as well. One way to remediate this is by setting the printer to cut between labels. This will force the printer to stop, cut and recalibrate on each label, lowering the chances of any small sensor variances building up as if multiple labels had been run through: How to Set Label Cutting Options in Brady Workstation.

Cleaning

Adhesive buildup can cause labels to feed inconsistently through the label path. Reference your user manual or this knowledge base for specific instructions to clean your printer (e.g. "BBP33 Clean").

Firmware

Update the firmware on the i5300 if you are experiencing this issue and the other troubleshooting steps did not fix the issue: i5300 - How to Upgrade the Firmware.

Issue persists? Contact Global Brady Technical Support Contact Information and provide your serial number How to Find Your Brady Printer Serial Number. Include the troubleshooting steps taken.

Important: The BBP30, BBP31 and BBP33 is obsolete and no longer repaired: Obsolete Brady Printers - No longer supported or repaired.