To extend cutter and printer life, we recommend printing tag stock (B-2551) without cutting in between each label. We suggest printing Tag labels in larger batches and setting the cut mode to Cut at End of Job. The Cut mode can be adjusted in the J2000 status monitor. J2000 - Output or Cut Mode Definitions.

When printing tag stock on the J2000, specifically J20-255-2551, you will have to offset the cutter in order for the printer to cut on the perforation.

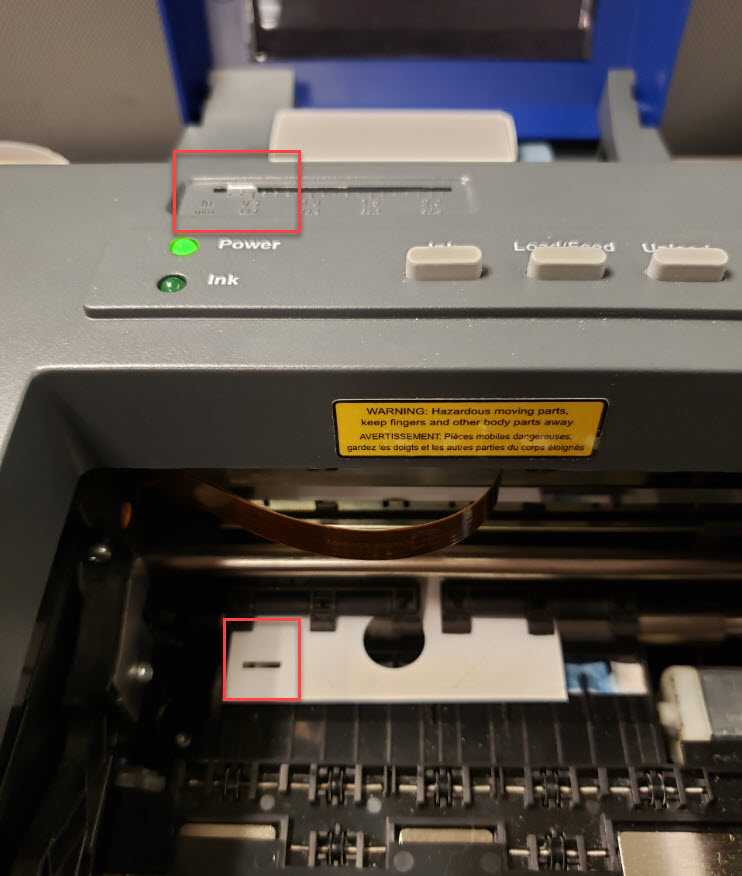

To reduce the variation of the cut location, please verify that the sensor has been positioned in the correct spot to detect the notch in the label material.

Make sure the sensor is positioned in appropriately

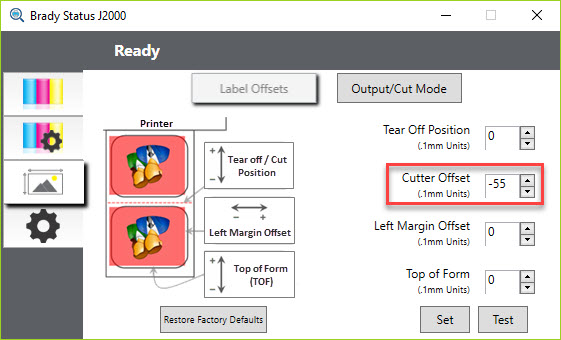

Once that is placed, set the cutter offset in the J2000 status monitor.

In order to get to the desired cut location, the printer may require an offset of around -55. Due to the printer scaling, this means an offset of about -5.5 mm See the screenshot of the status monitor below. This might not be exact for your application. -55 is provided as an estimate, your application may require more or less depending on the results.

Be sure to click the Set button after changing the offset to save the setting to the printer's firmware.

There is also a sample BWS tag file attached for testing purposes.