Thermal Printhead Maintenance

Thermal transfer printers have a print head that consists of a line of pixels that heat up to transfer ink from a ribbon to a label or tape. The printhead is the most expensive part of the printer to replace, and a damaged printhead produces poor print. Reference this article see examples of print quality issues caused by damaged or dirty print heads: Burned out pixels - white lines or vertical voids in the same spot on every label

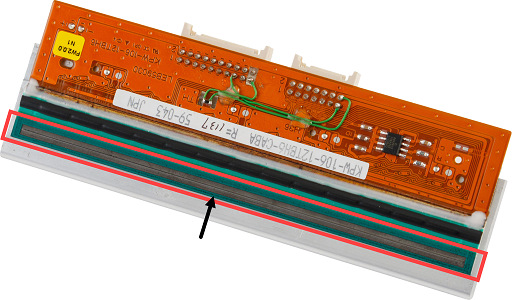

The thermal print head is the lower portion of the printhead surrounded by the green area.

Cleaning Best Practices

- Clean the printhead regularly after every roll of thermal transfer ribbon. If your printing environment is excessively dusty or humid, clean it more often. Clean with 90% isopropyl alcohol (IPA) on a foam tip applicator or on a soft cloth. We do not recommend using other cleaning solutions, such as Goo Gone or nail polish remover. Reference your printer's user manual or this knowledge base for specific instructions for your Brady printer model. Cleaning swabs are available on Bradyid.com.

- NEVER use any hard, metallic or abrasive objects, such as a screwdriver, to remove adhesives or other contaminants that may have built up on the printhead.

Printing Best Practices

- ALWAYS use a ribbon that is at least as wide as your label's complete web width - all labels (if multiple across) and the liner or carrier the labels are on. If the ribbon is more narrow than the media (label stock), the printhead will be exposed to the abrasive label stock

- Use the lowest darkness setting that prints well for your labels. This setting is not available on all printer models, reference your user manual or Best Practices for Adjusting Printhead Heat.

- Use the least amount of tension needed on the printhead. This adjustment is not available on all printer models reference your user manual or this knowledge base.

Related information