Note: See the "See Also" section for materials compliance information

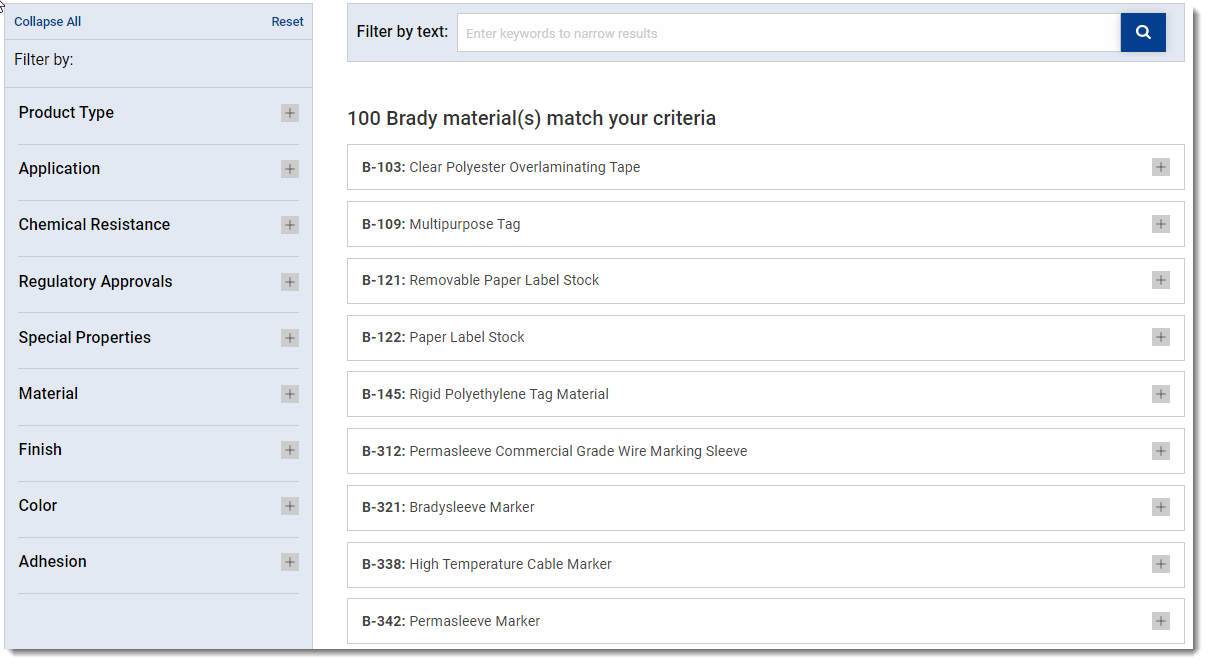

Find the best material for your specific application. Access the tool at this link.

Use this page to request a material sample.

- Note: This tool primarily includes materials recommended for Wire & Cable and Product Identification labeling.

Material Selection Best Practices

Material Selection Best Practices

It it is important to select a wire marker material that will last for your application. Some factors to consider:

- Contact with oil, water, chemicals or solvents?

- Self-extinguishing properties or requirements?

- Government or special specification requirements

- Dirt and environmental factors?

There are four main questions to ask when beginning the process of marking wires. These questions will help you select a wire marker that best suits your needs. Are you marking the wire before or after termination?

Self-laminating wire markers or wrap-around markers can be used either before or after termination. When using a wrap-around marker, the legend is visible from all sides since the marker completely wraps around the wire. A self-laminating marker is a special type of wrap around marker which has a clear portion that will wrap around and laminate the legend. This ensures that the legend is protected from spills and scratches.

Sleeve markers can only be used before termination because they must be slipped over the open end of the wire. These non-adhesive markers provide flexibility as they can be moved prior to being heat-shrunk. Once shrunk, these markers will provide a permanent marker which will stand up to harsh environments. Self-laminating wire markers provide long-lasting protection for custom-printed identification. PermaSleeveTM heat-shrink markers fit snugly around wires for maximum insulation protection and permanent identification. What gauge wire are you marking?

The size of the wire determines the length of the self-laminating/wrap-around marker or the diameter of the sleeve to be used. Most wrap-around styles can be used for a range of sizes. Brady's broad product offering will meet all your wire identification needs. Brady wrap-around markers can accommodate various gauges of wires. Will you print your own markers or purchase preprinted ones?

Preprinted markers are available in a large variety of stock legends, and custom legends are available for any large jobs. These markers come in a variety of packaging and formats for ease of use and ease of transport. They are ideal for any application.

Printable markers are meant to be printed with variable legends as needed. Various methods for this include: portable wire marking printers or computer software linked to thermal transfer, dot matrix, laser or ink-jet printers. An extensive array of sizes are available for every application. These printable markers offer the flexibility of printing legends on demand. They are also ideal for applications requiring long legends. In what type of environment will these wire markers be placed?

See Also