Body | When using the Brady Wraptor machine, if the machine displays an error message "Check Ribbon" this may indicate one of the following issues:

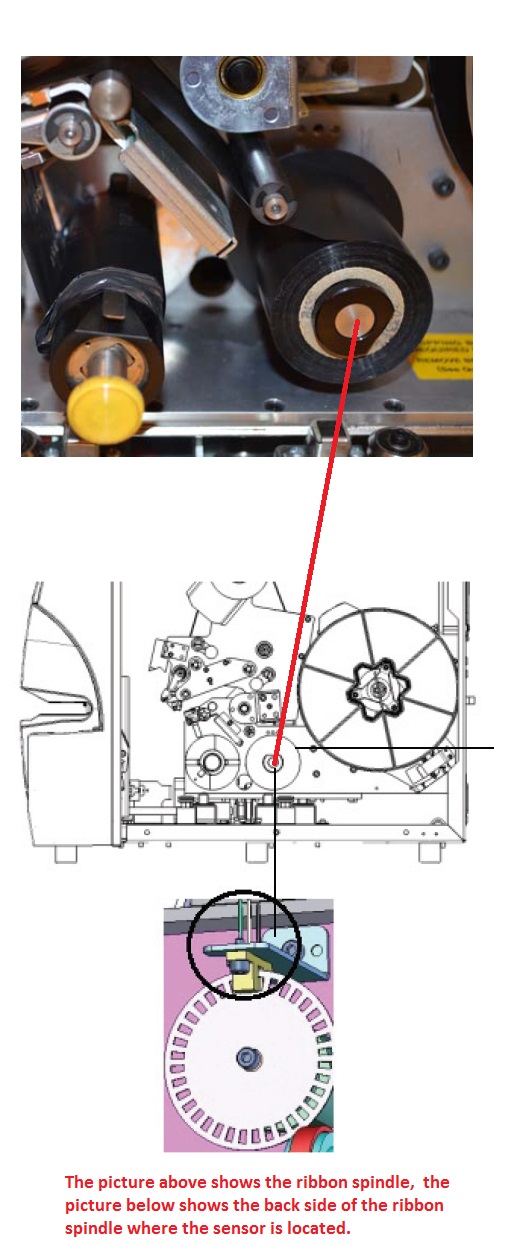

1. The ribbon sensor may be dirty, and should be cleaned using first compressed air, and then isopropyl alcohol. The ribbon sensor is on the backside of the ribbon spindle. When standing in front of the ribbon spindle, where new ribbon is installed, the sensor cannot be seen. It is on the backside of the ribbon spindle.

2. The ribbon may be routed incorrectly, see the label inside the lid of the Wraptor machine, looking at image #9 that shows the proper ribbon routing path. Uninstall and then properly re-install the ribbon, ensuring that the "Ink side" is facing UP.

If you are unsure about this, simply peel off a label and touch the sticky side to the surface of the ribbon that is facing up when the ribbon is installed. When you peel the label away, if there is ink on the label then it's installed correctly. If not, the ribbon is installed upside down.

3. The ribbon is under tension, if the sensor detects that one spindle is moving and the other isn't, it will think the ribbon is broken. Check to ensure the ribbon is not broken. If it is, simply advance it and tighten the ribbon uptake spindle to move past the break. If the ribbons continue to break, and/or the spindles are not turning, then the unit may require repairs. |

|

|---|