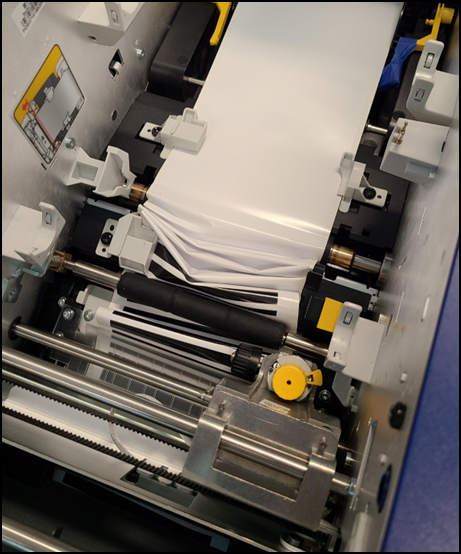

Body | IssueWhen printing 4" wide material, the BBP37 partially prints a label, then the label material jams. The printer may not throw an error the first time this occurs. Usually the printer will cut early, leaving the remaining printed label inside the printer. This issue may only occur when most of the label media has been used, as the smaller roll creates lower initial feedback position.

CauseThis can occur if the eject rollers are too tight. ResolutionLoosen the Eject Rollers. CauseThis can occur if the eject rollers are too tight. ResolutionLoosen the Eject Rollers.

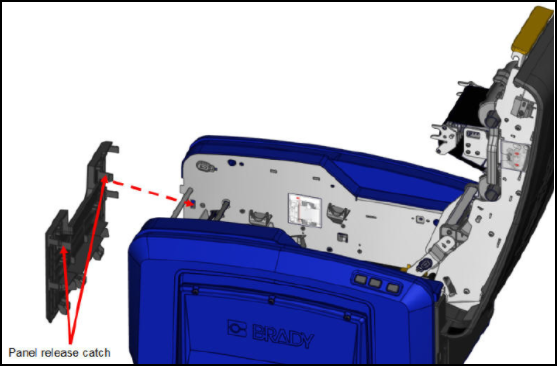

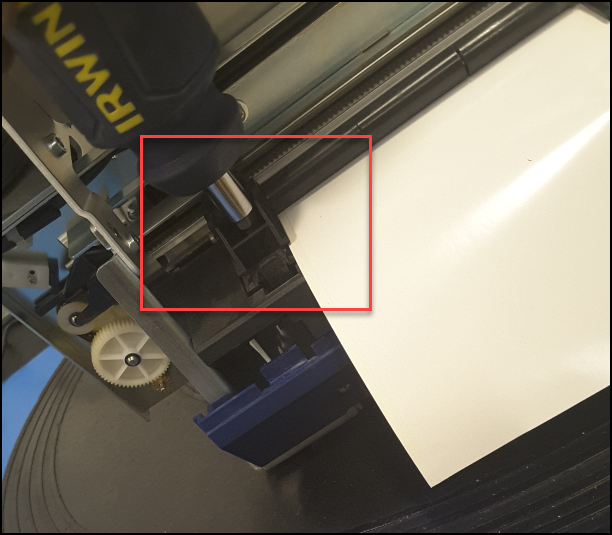

Tools needed: T20 Torx wrench1. Remove the front printer front panel.

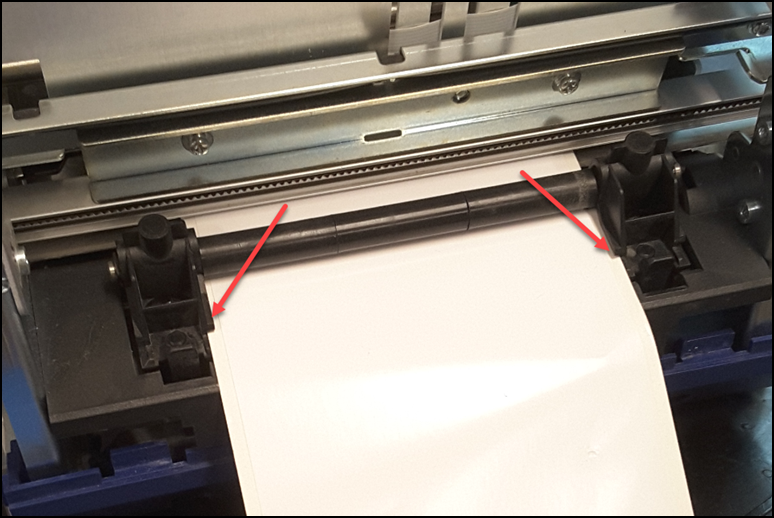

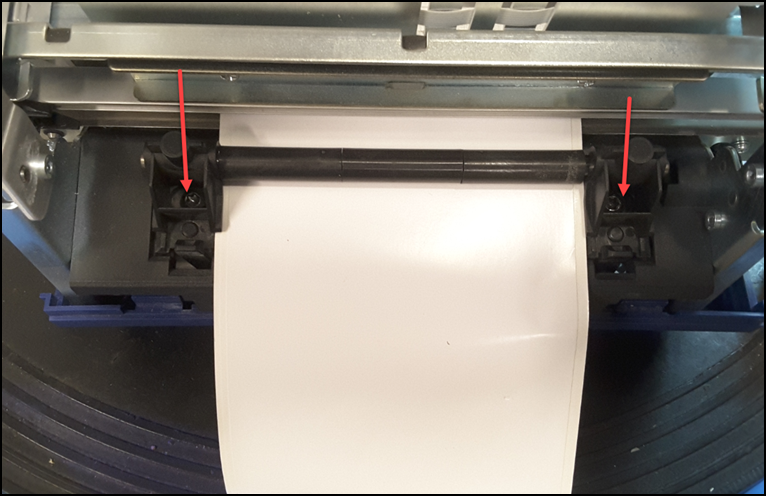

2. These black pieces need to be spaced slightly - there should be a small amount of wiggle room for the 4" media.

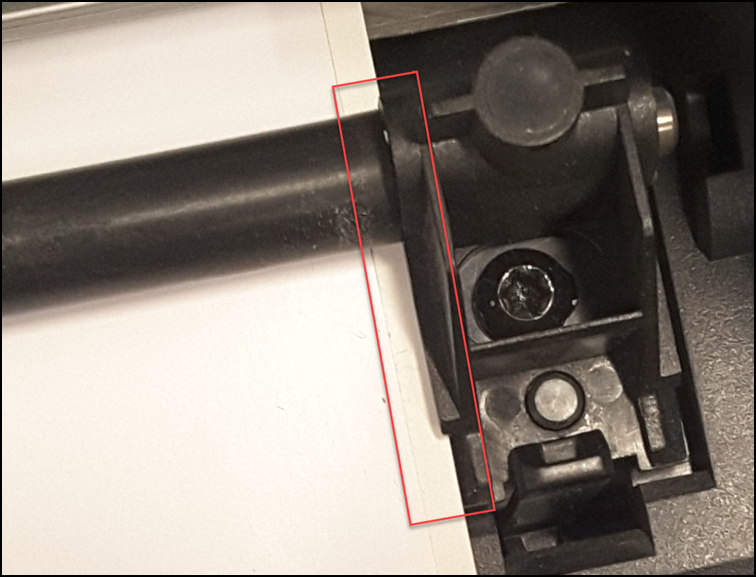

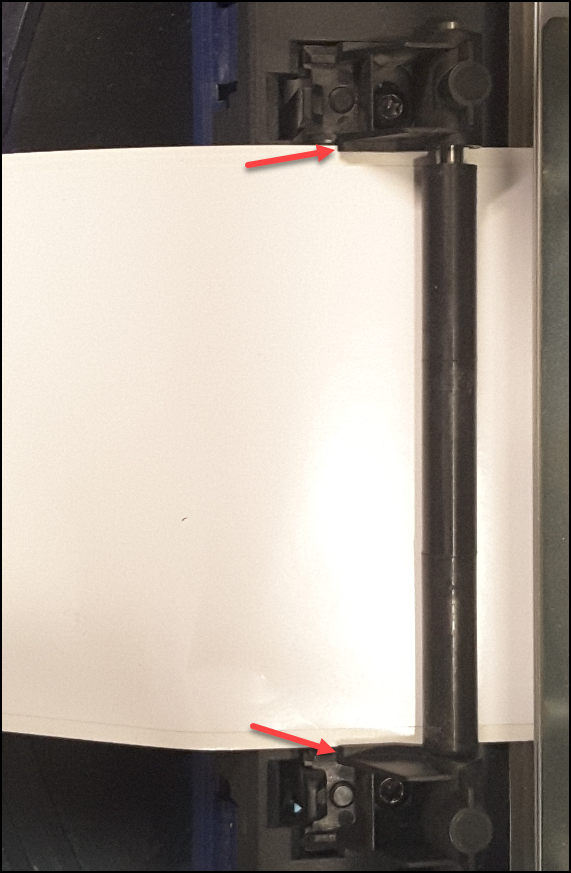

3. Locate the screws that loosed the exit guides. 3. Locate the screws that loosed the exit guides.  4. Loosen the torx screw with the wrench. 4. Loosen the torx screw with the wrench.  5. Position the guide so that it is not in direct contact with the label liner edge. 5. Position the guide so that it is not in direct contact with the label liner edge.  6. Perform this step for both sides, so that they are evenly spaced off the label liner edge. 6. Perform this step for both sides, so that they are evenly spaced off the label liner edge.

Note: Make sure a small portion of the liner edge remains under the lip of the guide, otherwise the material can become dislodged from the path, causing further jam issues. |

|

|---|